Metal Organic Framework (MOF)

With a group of enthusiastic engineers and inventors, we at Kerone are dedicated to expanding the frontiers of Metal Organic Framework (MOF) research and development. We are committed to using MOF's remarkable qualities to create useful solutions that deal with today's most important problems.

It was discovered that Metal Organic Framework (MOF) is a result of multiple chemical reactions. Researchers and product developers have been drawn to MOF due to its unique chemical and structural properties, which include its uniform pore topologies, variable porosity, flexibility in network topology, shape, size, and chemical functionality.

What are MOFs?

MOFs are composed of ligand molecules and metal ions arranged in three dimensions within crystalline frameworks. Metal-organic frameworks have a surface area and porosity of up to 7000 m2/g.

Extremely flexible control over the size and form of pores is made possible by the nearly infinite combinations of metals and linkers. Because of their cage-like structure, MOFs have a high surface area, which is just one of their many benefits. It is capable of serving as a filter to either absorb or trap specific chemical substances.

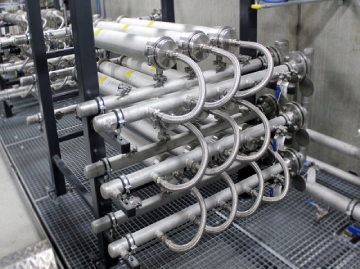

Commercial interest in MOF has grown in the areas of electrochemistry, sensing, energy storage, gas storage and separation, and purification. Our continuous approach for hydrothermal synthesis is compatible with such a market, even if the traditional means of making MOFs have traditionally been so expensive. Furthermore, we work together with several research groups to create new MOFs and switch from batch to flow production techniques.

Key Features of MOF

- Porous Structure

- Exceptional Surface Area

- Tunable Pore Size

- High Adsorption Capacity

- Innovative Catalysis

- Biocompatibility

- Active Research Area

Application

Related images