Coating Machine: Manufacturer, Supplier.

The Coating Machine is engineered to deliver high precision, controlled coating across a range of industrial substrates such as polymer films, fabric strips, metal sheets and paper rolls. Designed with automated PLC control systems, it ensures consistent layer uniformity and optimal coating thickness through variable speed regulation,temperature and humidity management and real time sensor feedback. The robust frame integrates roller drive technology for stable movement and anti-static discharge systems to maintain material integrity. Its modular structure supports multi-stage coating processes with seamless synchronization to upstream and downstream units like drying systems and fabrication machinery. Equipped with infrared heating elements, UV curing units, and air circulation modules, the machine facilitates rapid drying and effective surface treatment. Operational efficiency is enhanced through servo driven web tension controls,precision nozzle systems and fault diagnostics for minimal downtime. The inclusion of automated cleaning cycles and easy access maintenance panels ensures uninterrupted workflow and long term reliability. It supports varied functional needs including thin film coating, surface coating technology and specialized applications in packaging, electronics, automotive, textile and pharma manufacturing. Built for high volume output and environmental efficiency, this machine embodies core values of process optimization, material compatibility and energy conscious operation.

Types of Coating Machines offered by Kerone are as below:

Gravure Coating System

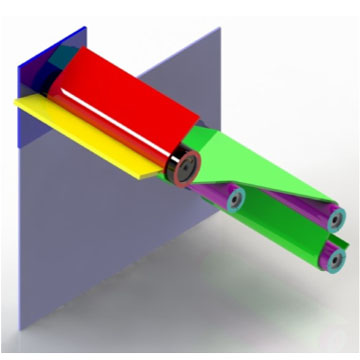

Reverse Roll Coating Machine

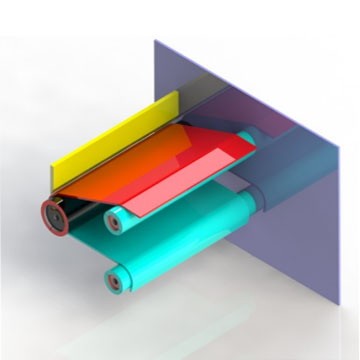

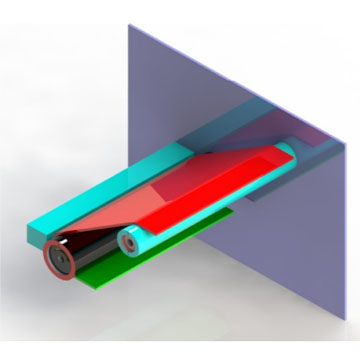

Knife Over Roll Coating Machine

Knife Over Roll Coating Machine

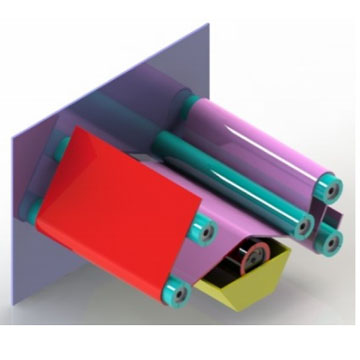

Metering Rod Coating Machine

Slot Die Coating System

Curtain Coating Machine

Immersion / Dip Coating Machine

Immersion / Dip Coating Machine

Pilot Coating Plant

Spray Coating Machine

Fabric Coating System

Web Coating System

Impregnation Plant

Advantages:

1.Refined Durability: Coating machines apply protective layers, significantly extending material lifespan by shielding against corrosion, wear and environmental damage.

2.Improved Appeal: Precision coating ensures uniform, high quality finishes, enhancing product visuals for better marketability and customer satisfaction.

3.Increased Efficiency: Automated coating systems streamline processes, reducing manual labor and accelerating output with consistent results.

4.Cost Effective Operations: Advanced coating technology minimizes material waste and energy consumption, lowering production costs over time.

5.Versatile Application Range: Coating machines handle diverse materials like metals, plastics and ceramics,catering to industries from automotive to electronics.

6.Improved Functionality: Functional coatings add properties like anti-slip, waterproofing or thermal resistance, improving product performance.

Application Industries of Coating machines:

1.Electronics

2.Automotive

3.Pharmaceutical

4.Food & Beverage

5.Chemical

6.Medical Equipment

7.Packaging

8.Steel Production

9.Textiles

10.Consumer Goods

Why Choose Us:

Kerone is one of the globally recognized manufacturer and supplier of heating /cooling and drying products including dryers,process equipment, radio frequency heating system and many other associated products manufactured with best quality. For over more than 50 years, we have been driving innovation in the powder coating industry. Our continuous advancements are focused on improving coating speed and maximizing powder efficiency,helping our customers increase productivity and profitability across all types of products and applications.

1.Certified Commitment to Quality: We uphold stringent global standards with ISO 9001:2008, ISO 9001:2015,EMS 14001 and OHSAS 18001 certifications, ensuring every product meets rigorous quality and safety benchmarks.

2.Creative Ideas: Our ability and knowledge brings advanced, custom engineered heating,cooling and drying systems that demonstrate operational efficiency.

3.Eco-Friendly Focus: We prioritize environmentally responsible manufacturing, providing solutions that minimize resource consumption and use less energy.

4.Legacy of Excellence: Our legacy of excellence enables us to deliver reliable performance and tailored process equipment for a wide range of industrial applications.

5.Customer Friendly Approach: We offer ethical and on-time service, ensuring maximum value and satisfaction for all our esteemed customers.