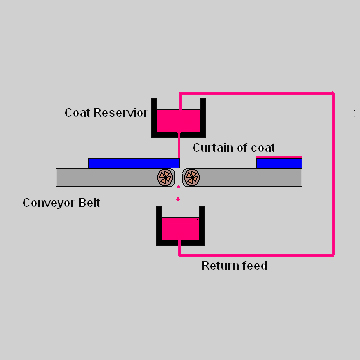

Curtain Coating

Curtain coating process creates an uninterrupted curtain of fluid that falls onto a substrate. The object to be coated, such as a door, is passed along the conveyor at a controlled speed and so receives even coating on its upper face. The curtain is created by using a slit at the base of the holding tank, allowing the liquid to fall upon the substrate.

Uses

- Promotional, opening price-point and moderate market levels.

- Cookware: Interiors and exteriors.

- Bakeware

- Small electrics.

Advantages

- Speed: This system can coat from 3,000 to 4,000 pieces per hour

- Minimum personnel required.

- Virtually no waste: Since the small amount of unused coating is cycled back into the system, this method wastes less coating than any other.

- Aesthetics: The only non-spray process that imparts a smooth, glossy finish, with no track marks.

- Flexibility: Disks can be as thin or as thick as specifications require.